Investment casting is a casting technique. It involves injecting liquid wax into a metal mold to create a wax pattern that is identical to the desired casting. Subsequently, multiple layers of refractory ceramic materials, such as clay, are applied to the exterior of the wax pattern. Upon heating, the wax melts and flows out, resulting in a hardened ceramic shell. This ceramic shell is then fired to remove any residual wax and to strengthen the shell. Molten metal is poured into the ceramic mold, and after the metal cools and solidifies, the ceramic shell is broken away to reveal the finished metal casting.

Lost foam casting is a type of evaporative-pattern casting process that is similar to investment casting except foam is used for the pattern instead of wax.

This casting process is advantageous for very complex castings that would regularly require cores. It is also dimensionally accurate, maintains an excellent surface finish, requires no draft, and has no parting lines so no flash is formed.

SHENGRONG provides lost foam castings range from 1 kg to 1,000 kg, Maximum size of the flask is 1100 x 1100 x 1000 and produces casting volumes from prototype to 20,000 tons per year.

No-brake resin sand molding is a sand molding process where synthetic liquid resin is mixed with the sand, and the mixture hardens and cools at room temperature. The casting is formed by pouring liquid metal into the resulting mold cavity after the sand mixture is fully cured and the mold halves are assembled together. This process takes place in a normal atmosphere without adding heat to the mold prior to the pour.

Casting Materials

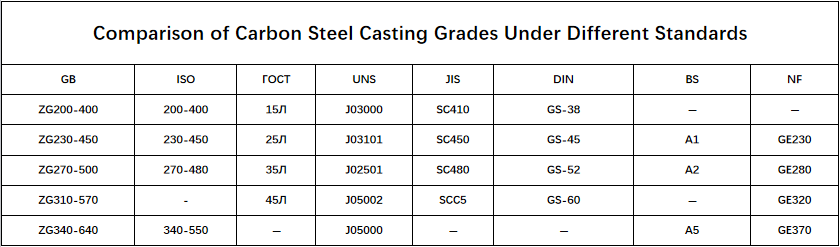

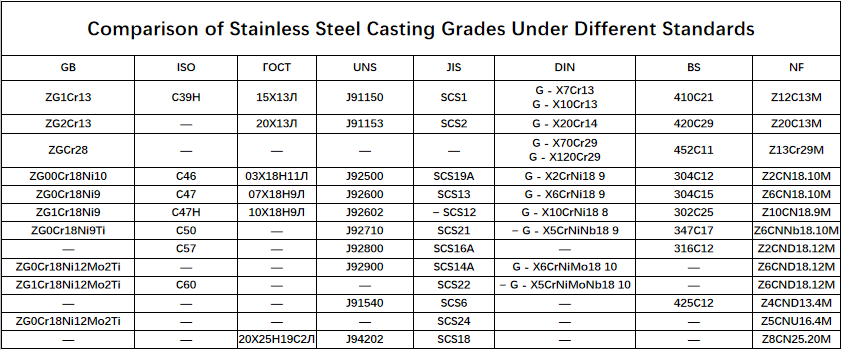

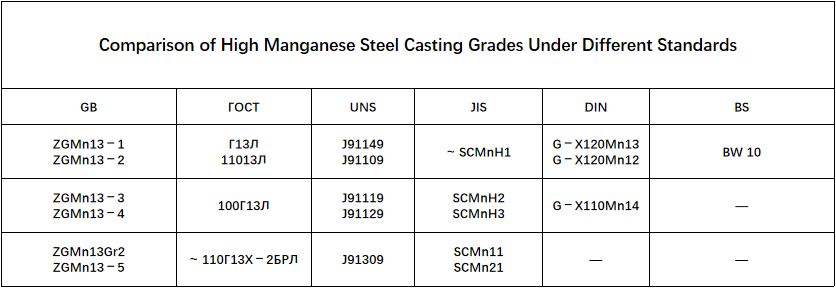

SHENGRONG Casting is capable of producing precision investment casting products in virtually any air-melt alloy. Our foundry specializes in casting stainless steel, carbon steel, alloy steel, and high manganese steel. We have provided precision casting services to a variety of industries, including automotive, rail, construction equipment, agriculture Machinary, and Petrochemical engineering.

Shengrong Factory

About SHENGRONG steel casting

SHENGRONG is a foundry located in Xuyi County, Huai’an City, Jiangsu Province, dedicated to providing precision investment castings. Jiangsu Province, where Shengrong Foundry is situated, is one of the most industrially developed regions in China, boasting a comprehensive range of industrial sectors and hosting numerous renowned automotive design and manufacturing companies, rail transportation companies, high-tech industries, and other manufacturing sectors. Since 2015, Shengrong Precision Casting Company has been producing investment castings. With strong capabilities in casting stainless steel, carbon steel, alloy steel, high manganese steel, and more, we have collaborated with numerous clients to solve their casting challenges in innovative and cost-effective ways. Our management team possesses extensive experience in the investment casting industry, which ensures higher-quality products and on-time delivery for our customers. We operate under a single-tier management system, enabling us to respond swiftly to your needs. SHENGRONG Casting Company has always been committed to providing high-quality precision investment castings and components. We are an ISO 9001:2015 and IATF 16949 certified precision investment casting foundry located in Maba Town, Xuyi County, Huai’an City, Jiangsu Province. Feel free to contact us anytime!